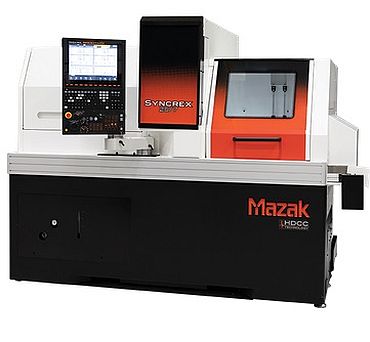

Mazak’s Syncrex Turning Machine Features 7-Axis Configuration and 5 Spindle Motors for High-Speed Production

Mazak's SYNCREX 25/7 Swiss-style turning machine is ideal for cutting real-world parts.

With a maximum bar diameter of 1" (25mm), the SYNCREX 25/7 powers through high-speed production of small, precise parts in a seven-axis configuration that includes five spindle motors and standard 10,000 rpm main and sub spindles.

Like all models in the series, the SYNCREX 25/7 is a sliding headstock machine constructed on the Mazak High Damping Composite Casting (HDCC). This unique high rigidity base provides greater vibration damping characteristics, less thermal growth and greater part surface capabilities when compared to a cast iron base machine, while the sliding headstock allows manufacturers to run full bar capacity with no special bar end prep.

The Mazak SYNCREX 25/7 is equipped with the MAZATROL SmoothSt CNC with 15" touch-panel for easy input of setup and programming data. Intuitive user-friendly screens make it quick and easy to touch off tools and prepare the machine for automatic cycles, which regains production time and lessens setup.

VIDEO: SYNCREX Swiss-Style Machining

The optional Mazak Swiss Setup Assist (MSSA) further enhances fast and easy production, along with the optional Mazak Dynamic Chip Control (MDCC) functionality that increases chip-management performance.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::